In order to reduce waste at our manufacturing sites, DuPont has established an onsite recycling facility alongside our Tyvek® manufacturing lines in Luxembourg. The facility uses a sophisticated shredder-feeder-extruder combination system that can process all types of Tyvek® production scrap and turn it into pellets for reuse. This investment in mechanical recycling makes it easy and efficient to re-process post-industrial waste back into high-density polyethylene (HDPE) granulates for reuse.

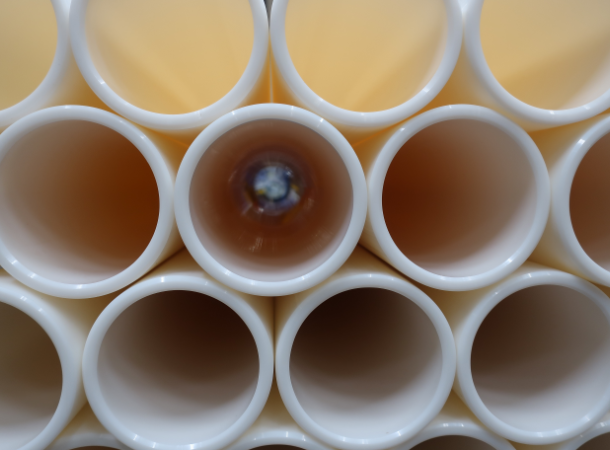

To provide tangible circular benefits, the recycled granulates are then used to produce plastic cores around which Tyvek® can be wound for storage and shipping. We are working closely with packaging supplier Sonoco to create these winding cores. They are currently extruded in Sonoco’s facility in Germany and then returned to our manufacturing plant in Luxembourg. We then wind sheets of newly produced Tyvek® around cores produced from 100% recycled Tyvek®, whose quality is controlled through our quality management system. Additional benefits of these cores include low particle emission, strength and dimensional stability.