Okay Paper—Innovation in “Made in Valtellina” Tissues

General

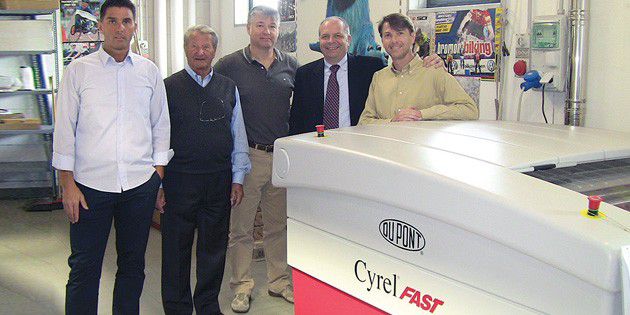

Located in an area far from the traditional Italian industrial and commercial hubs, is one of the most important Italian manufacturers of tablecloths, placemats, napkins, paper and wadding tissues: OKAY Paper. The company was established in 1969 by the current CEO, Gilberto Corti, now assisted by his sons Stefano (Production Manager), Paolo (Commercial Manager) and Michele (Plant Manager). “Since we started up”, says Gilberto Corti determinedly, “the company has found a niche in the market for our strong spirit of innovation and quality.

OKAY Paper has been a DuPont customer for more than 25 years, and in 2015, they installed a Cyrel® FAST thermal technology system. Michele Corti: “this choice has enabled us to improve printing quality considerably, succeeding in improving the ink transfer to the substrate, which also enables the reproduction of very fine screens, and improves the nuances. Printing on tissue is very delicate: the substrate can be altered if the ink transfer is not properly controlled. This is why a quality plate is synonymous with guaranteeing the finished product”.

Related Products

Cyrel® Flexo Plates

DuPont™ Cyrel® flexo plates deliver higher quality at higher speeds in a wide range of package printing applications.

Flat Top Dot Workflow Solutions

DuPont offers two flat top dot workflow solutions: Cyrel® DigiFlow and Cyrel® DigiCorr

Cyrel® Round Systems

Cyrel® Round Systems offer a complete digital flexographic sleeve production solution that delivers highly precise registration and eye-catching print quality.

Cyrel® Solvent Workflow

The Cyrel® solvent workflow consists of flexographic photopolymer plates and sleeves, platemaking equipment and washout solutions

Cyrel® FAST Thermal Workflow

Cyrel® FAST thermal plate processing technology uses solvent-free thermal processing to produce a press-ready finished flexo plates