How can one print packaging faster, more beautiful and with a smaller environmental footprint?

Download in other languages

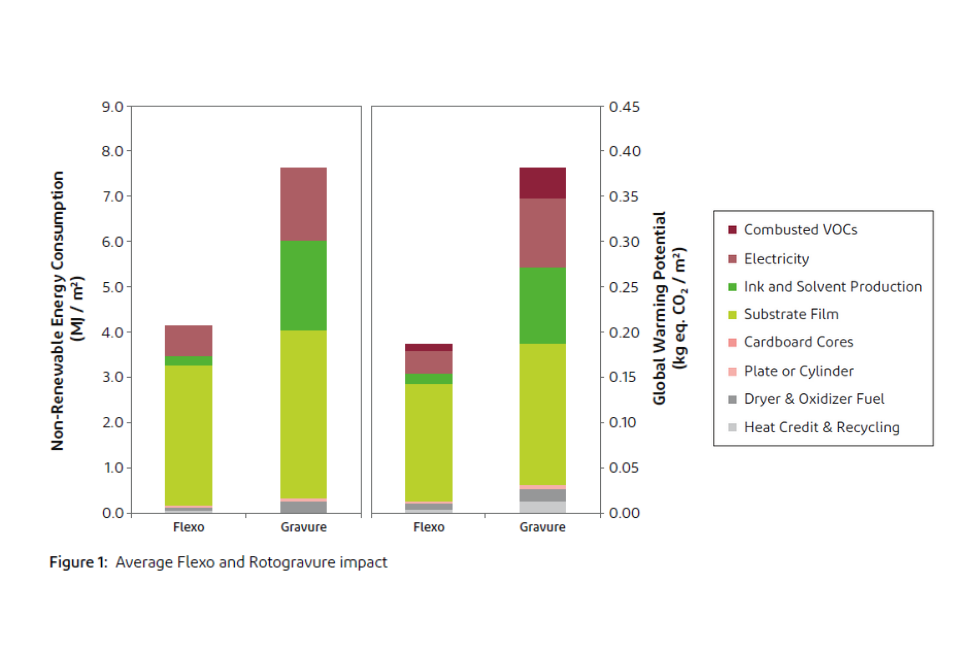

Comparing Flexo to Gravure

The first step in the Life Cycle Assessment was to compare the carbon footprint of flexo to gravure based on comparable substrate and printed area.

Flexographic printing leads to 46% lower NRE consumption and 51% lower GWP than gravure printing

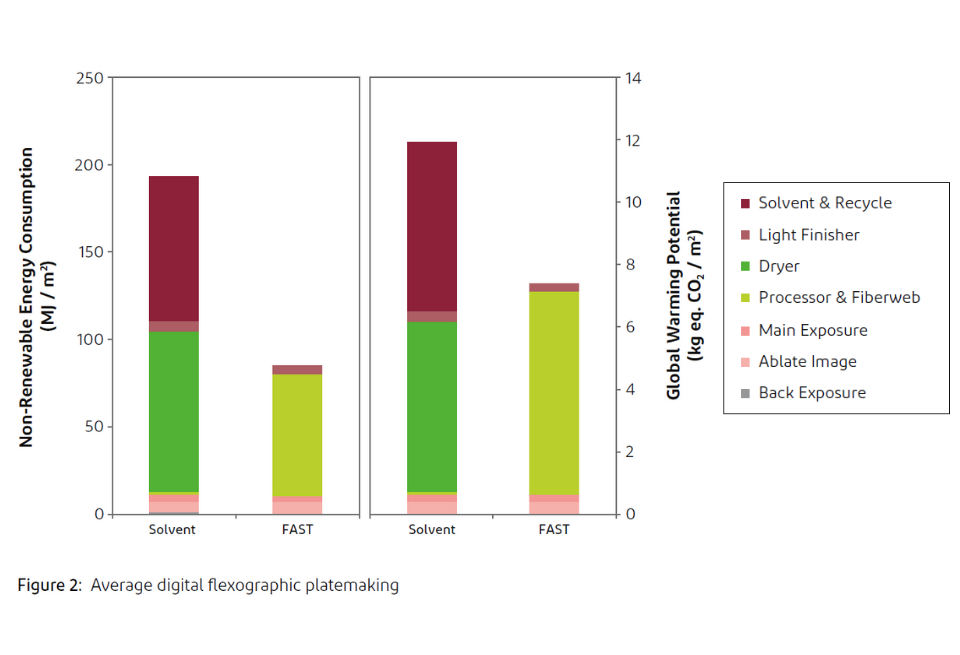

Comparing Cyrel® solvent to Cyrel® FAST

The second step in the Life Cycle Assessment was to compare the carbon footprint of solvent to Cyrel® FAST processing based on an equivalent volume of processed plates.

Platemaking with Cyrel® FAST leads to 56% lower non-renewable energy consumption and 38% lower global warming potential

The original DuPont life cycle assessment (LCA)(1) has been updated using the Ecoinvent 3(2) database for relevant inputs and the Intergovernmental Panel on Climate Change (IPCC) 5th Assessment(3) values for the global warming potential impact method. The impacts studied remained the same as the original study (global warming potential (GWP) and non-renewable energy (NRE) consumption).

The environmental impacts considered in this study are primary non-renewable energy consumption (fossil and nuclear) and global warming potential.

An update from the original study is the use of the latest GWP impact assessment methodology. A period of 100 years is customary and the Intergovernmental Panel on Climate Change (IPCC) (100 yr) methodology is applied in this study using the values from the 5th Assessment.

Customer Testimonials & Success Cases

Related Products

Cyrel® FAST Thermal Workflow

DuPont™ Cyrel® FAST technology brings your package to life faster, cleaner and more reliably. We turn complicated operations into solutions making your business more efficient, robust and sustainable.

Cyrel® FAST Thermal Equipment

The DuPont™ Cyrel® FAST 2000 & 3000 TD is the result of 20 years of engineering experience in thermal processors. The fully thought over design takes reliability, consistency and quality to today's required levels – and beyond.

Take a closer look at how you can boost productivity and drive efficiency.